It’s the first factory digitalized with 5G for industrial processes in Spain

- Industrial machinery is connected with new 5G technology to process the data generated in real time thanks to edge computing.

- With this data, the factory is virtualized so that it can perform massive simulations that allows optimal decision-making concerning operations in an intelligent, connected, flexible and wireless factory.

- The project started as a collaboration between Mobile World Capital Barcelona, Telefónica and Gestamp, within the framework of the 5G Barcelona initiative, as part of its vision to move forward in digitalization.

Madrid, November 10th, 2020. Telefónica and Gestamp, a multinational company dedicated to the design, development and manufacture of automotive components, have implemented a 5G-connected factory use case in one of its plants in Barcelona to advance in the road to Industry 4.0 thanks to this technology.

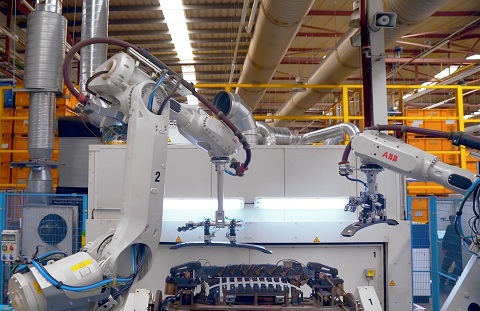

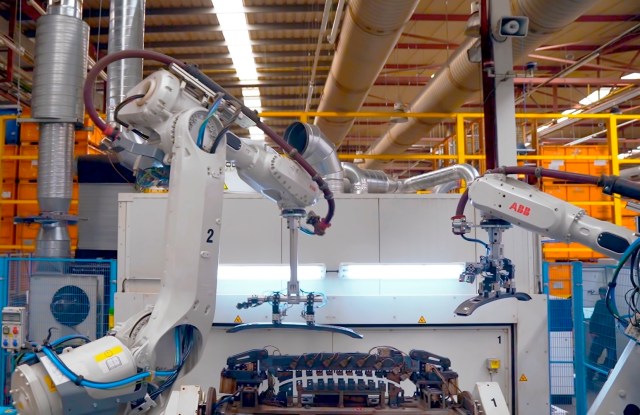

The project, the first digitised factory with 5G in Spain for industrial processes, consists of virtualising a complete factory and connecting it to 5G to improve the decision-making process. Specifically, Telefónica has connected the physical elements of the plant, such as the robotic welding cells, via 5G to capture and process in real time the data produced by this industrial equipment during its operation through the nearby computing capabilities that Multi Access Edge Computing (MEC) enables.

In this way, the data collected from the different industrial devices is processed more closely than if it were in the cloud, allowing it to be analysed in real time to make the concept of the intelligent factory a reality.

The whole process is completed with the connection of the physical elements using a digital twin, a virtual model of the factory processes that is fed with the data received through 5G, making it possible to carry out simulations and optimise the decision-making process, thus facilitating the smoother factory operations.

The final aim is to be able to make the best possible decisions in a flexible, accurate way by searching for the best scenarios suggested by the model.

For the data processing and simulations required in the digital twin, ample computing, memory and storage capacity is required. All these capabilities are offered by Virtual Data Center in Edge, a virtualised environment that Telefónica is deploying in a number of locations. The project employs the infrastructure located in Barcelona, very close to the Gestamp factory.

Both the 5G client equipment at Gestamp and the mobile network have been set up so that the traffic generated in the factory reaches the MEC directly, without making unnecessary jumps in the network or through the internet, which ensures low communication latency with the digital twin.

A survey was undertaken and subsequent laboratory tests carried out with 5G-router prototypes and solutions in order to select the final devices that best adapt to project requirements.

As René González, Advanced Manufacturing Corporate Director at Gestamp said, “the company has been working for years on a smart and connected factory model that seeks to increase the flexibility of its industrial facilities. 5G connectivity project is a key element within this strategy. The adoption of 5G technology is part of a process that takes place at a time of great technological disruption in the automotive industry, with the emergence of electric and connected cars. It also occurs within an environment in which vehicle manufacturers offer increasing customisation in their models, so manufacturing has to adapt and add the layer of software and intelligence that allows us to do things differently.”

Mercedes Fernández, Innovation Manager at Telefónica Spain, highlighted the fact that “in this case, together with Gestamp, we are making the concept of a connected factory a reality and taking an important step in Industry 4.0, one of the keys to the development of 5G and Edge Computing. Telefónica therefore deems it essential to make progress in the use of new technologies in both the professional and individual fields in order to make sense of 5G, so that it can offer solutions and respond to the users demands by contributing to the definition of applications that improve their processes and transform the way they do things.”

With this project, Telefónica and Gestamp mark a new milestone in the implementation of 5G in Spain, which the operator pioneered in 2018 with its 5G Technological Cities. This initiative has made it possible to develop new technologies that have served to build and consolidate the 5G ecosystem. From the outset, Catalonia has been a priority scenario in 5G Technological Cities. To date, Telefónica has carried out more than twelve 5G projects, some of which have been of global relevance as they were exhibited at Mobile World Congress.

In these projects, the level of collaboration with public administrations, research centres and organisations such as Mobile World Capital merits special mention. This project started, in fact, as a collaboration between Mobile World Capital Barcelona, Telefónica and Gestamp, within the framework of the 5G Barcelona initiative, in its shared purpose to move forward in digitalization.

About Gestamp

Gestamp is a multinational specialized in the design, development and manufacture of highly engineered metal components for top vehicle manufacturers. It develops products with an innovative design to produce lighter and safer vehicles, which offer improved energy consumption and a reduced environmental impact. Its products cover the areas of body-in-white, chassis and mechanisms.

The company is present in 23 countries with 112 manufacturing plants, 13 R&D centers and a workforce of nearly 43,000 employees worldwide. Its turnover was €9,065m in 2019. Gestamp is listed on the Spanish stock market under the GEST ticker.

For inquiries to Telefónica:

Tel: (+34) 91 482 38 00

email: [email protected]

For inquiries to Gestamp:

Tel: (+34) 619 406 058

email: [email protected]

https://www.gestamp.com/medios/