The robot described by the Czech author Karel Capek in his play ‘R.U.R.’ (Rossum Universal Robots) has nothing to do with today’s robots. For years, the development of programming has revolutionized the landscape of machine automation, and industrial robots are already part of the new production landscape.

The significant growth experienced by robotics is due, on the one hand, to the evolution of programming, since both branches go hand in hand. This, together with the deployment of technologies such as the 5G network, has in turn favored the connectivity of the Internet of Things, leading to what is now known as the Smart Factory, or connected factory, within the Industry 4.0 scenario.

This type of automation is already key in a good number of processes in industrial production, so much so that they are already essential complements in the production of sectors such as automotive, electronics and technology, food, logistics, pharmaceuticals, and aerospace, among many others.

First industrial robots

The use of industrial robots has already become a megatrend, with spending on robotics by companies expected to reach nearly $66.9 billion by 2025, according to growth forecasts by the International Federation of Robotics.

But the first steps in this branch of robotics were taken by inventor George Devol, creator in 1948 of what later became the first robotic arm called Unimate, whose evolution is today an essential tool in the assembly lines of factories in the automotive sector. Devol together with Joseph F. Engelberger, physicist and engineer, founded Unimation, a pioneering company that manufactured industrial robots in the world, and it was General Motors itself that installed these first robotic arms, thus initiating the transformation of its assembly lines towards automation.

Since then, the area of industrial robotics has continued to grow hand in hand with the development of other technologies such as the use of cameras and sensors, and improvements in software and hardware, improving their ability to manufacture and produce any type of object. As early as the 1960s and 1970s, robotic arms made a qualitative leap, and no longer only assembled cars or moved heavy objects on production lines. They began to perceive and understand their environment, albeit in a limited way, such as the mobile robot Shakey.

Now industrial robots are becoming more sophisticated and can perform increasingly complex tasks, but, as with digital tools, technological innovations, including robotics, are becoming more and more accessible, and are finding their way into the manufacturing processes of small and medium-sized companies.

How do industrial robots work?

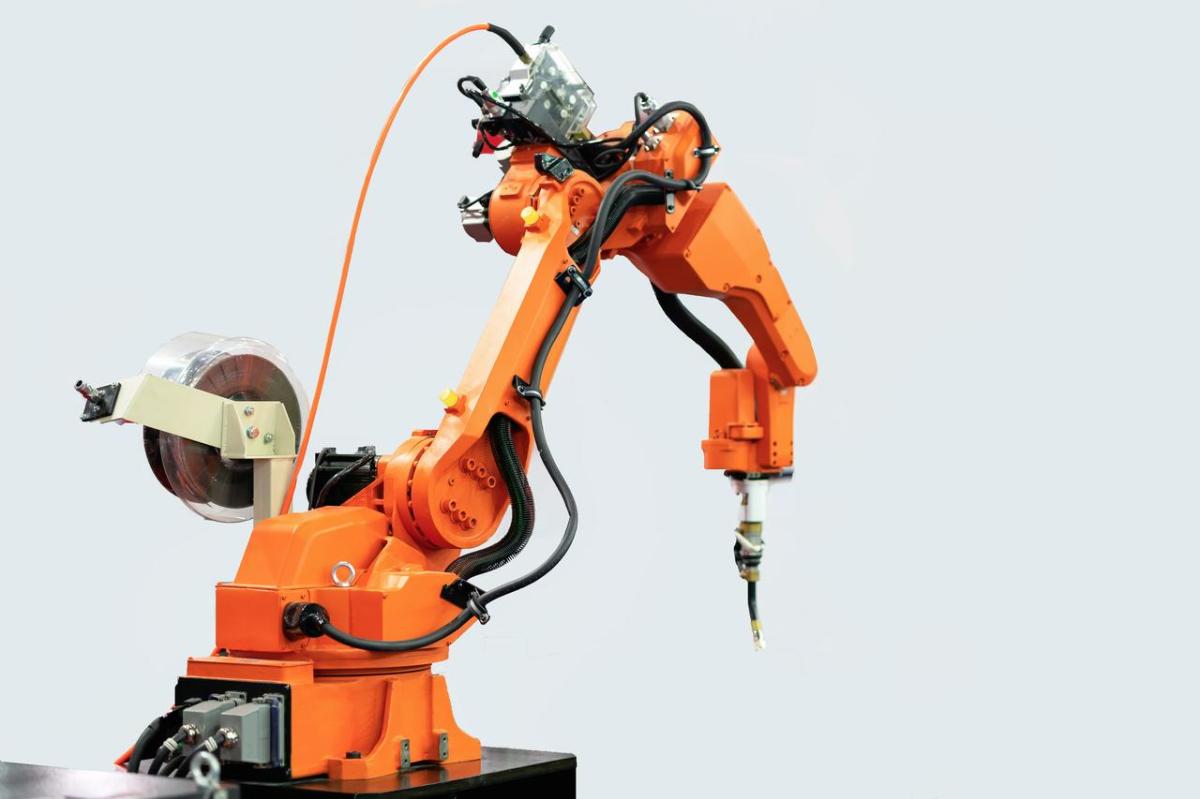

These collaborative tools are programmable and multifunctional, and one of the most important components is the controller. It is the brain of the robot and is where its movements are controlled, through the computer system that will program the instructions of the tasks to be performed.

And to provide them with the precision of movements, they have installed a series of sensors that allow them to control both the space to move in a specific way, as well as pressure sensors, to perform the work of maximum precision.

And all this is done thanks to robotics programming and the development of computer languages applied to this discipline, such as C/C++, which has resulted in a very broad field of robotic software.

The aim is that these machines can do all kinds of tasks in the industrial sector, such as drilling and cutting, which requires great precision and speed, this type of cutting can be done with a laser to cut thick materials without wearing out the blade, they can also weld and melt, pack and palletize, handle and transport goods in warehouses, and even monitor the quality of processes.

What types of robots are there in the industry?

Although the most commonly used manufacturing robot is the robotic arm, controlled by a computer (controller), these can be adapted according to the type of activity they are going to perform, thanks to the part called end effector, or end-of-arm tool, i.e. the tool that executes the activity, and which varies according to the task for the specific task to be performed.

The most common robots in the industry are manipulators. They are characterized by having a structure in the form of an articulated arm (SCARA) with up to 6 axes or joints, which gives them great mobility to perform tasks such as assembling and welding parts, painting, packaging, and palletizing, among many others. In addition, they can be Cartesian, if they move in the 3 axes (X,Y,Z) or if they have wheels to move in different directions they are considered mobile robots. The latter is very useful for transporting materials or products both in the production sector and in the logistics sector.

In addition, industrial robots can be collaborative, i.e., they are those designed to work together with people and collaborate in the tasks of the operators. These are highly evolved robots since they are equipped with sensors and cameras that allow them to detect the presence of operators in order to adapt their movements and avoid any type of accident.

Robots can also be autonomous, they are also very advanced and are equipped with cameras, sensors and navigation systems that allow them to move and perform tasks autonomously and do not need human supervision.